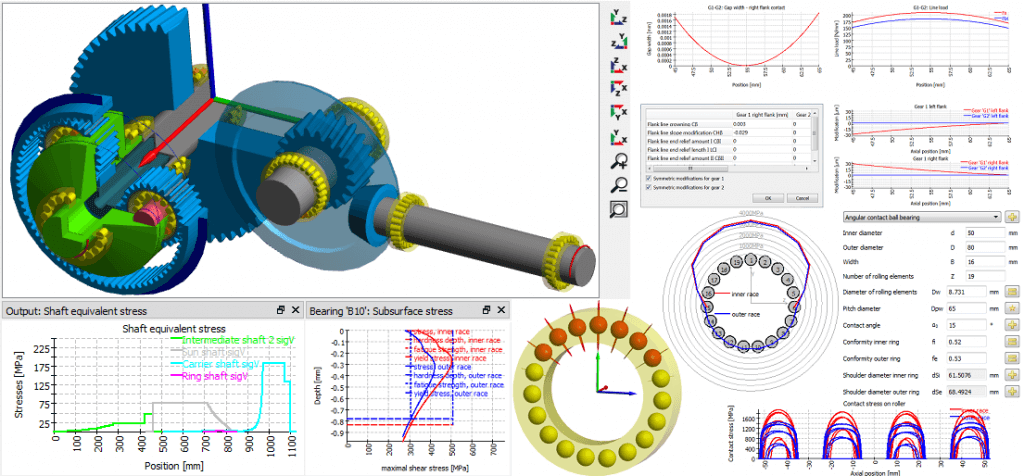

At Aetna, our design engineers always work directly with customers to develop not just solutions, but the types of customized solutions they need to meet the unique challenges they face. They use advanced engineering tools including Solid Works, AutoCAD, Finite Element Analysis (FEA) and MESYS to design products and analyze their performance. Our engineers have access to standard bearing calculations as well as the very sophisticated MESYS, a state of the art suit of software specifically designed for analysis of bearings and bearing systems. MESYS in particular gives our engineers the ability to design and validate a wide range of bearing types and optimize them to your application. This in turn assures products will perform as needed and that costly testing will be minimized. Our raceway profiles are a subject of pride at Aetna. Our design engineers carefully optimize raceway profiles to maximize load ratings, speed limits and fatigue life. Special consideration is given to “design for manufacturing” to ensure optimal residual raceway stresses for superior performance.

At Aetna, our design engineers always work directly with customers to develop not just solutions, but the types of customized solutions they need to meet the unique challenges they face. They use advanced engineering tools including Solid Works, AutoCAD, Finite Element Analysis (FEA) and MESYS to design products and analyze their performance. Our engineers have access to standard bearing calculations as well as the very sophisticated MESYS, a state of the art suit of software specifically designed for analysis of bearings and bearing systems. MESYS in particular gives our engineers the ability to design and validate a wide range of bearing types and optimize them to your application. This in turn assures products will perform as needed and that costly testing will be minimized. Our raceway profiles are a subject of pride at Aetna. Our design engineers carefully optimize raceway profiles to maximize load ratings, speed limits and fatigue life. Special consideration is given to “design for manufacturing” to ensure optimal residual raceway stresses for superior performance.

Aetna design engineers use Finite Element Analysis (FEA) software to optimize bearing designs. Since many applications are in dusty and contaminated conditions, FEA is also employed to analyze our bearing seals to keep contamination out.

Aetna design engineers use Finite Element Analysis (FEA) software to optimize bearing designs. Since many applications are in dusty and contaminated conditions, FEA is also employed to analyze our bearing seals to keep contamination out.